Understanding a Lifecycle Analysis (LCA) for Packaging

With businesses under increasing pressure to adopt sustainable practices, packaging is a critical (and often easy) area for improvement. A Lifecycle Analysis (LCA) is a scientific method that helps companies assess the environmental impact of a product throughout its entire lifecycle, from raw material extraction to manufacturing, transportation, use, and disposal (often referred to as "cradle-to-grave"). Because of the consistent framework used, LCAs are also useful for comparing the carbon impact of different materials too.

Why are LCAs Essential for Sustainable Packaging?

An LCA provides data-driven insights into the environmental footprint of packaging materials. This gives businesses a means of making informed decisions about which materials to use and how to optimise their supply chains for sustainability.

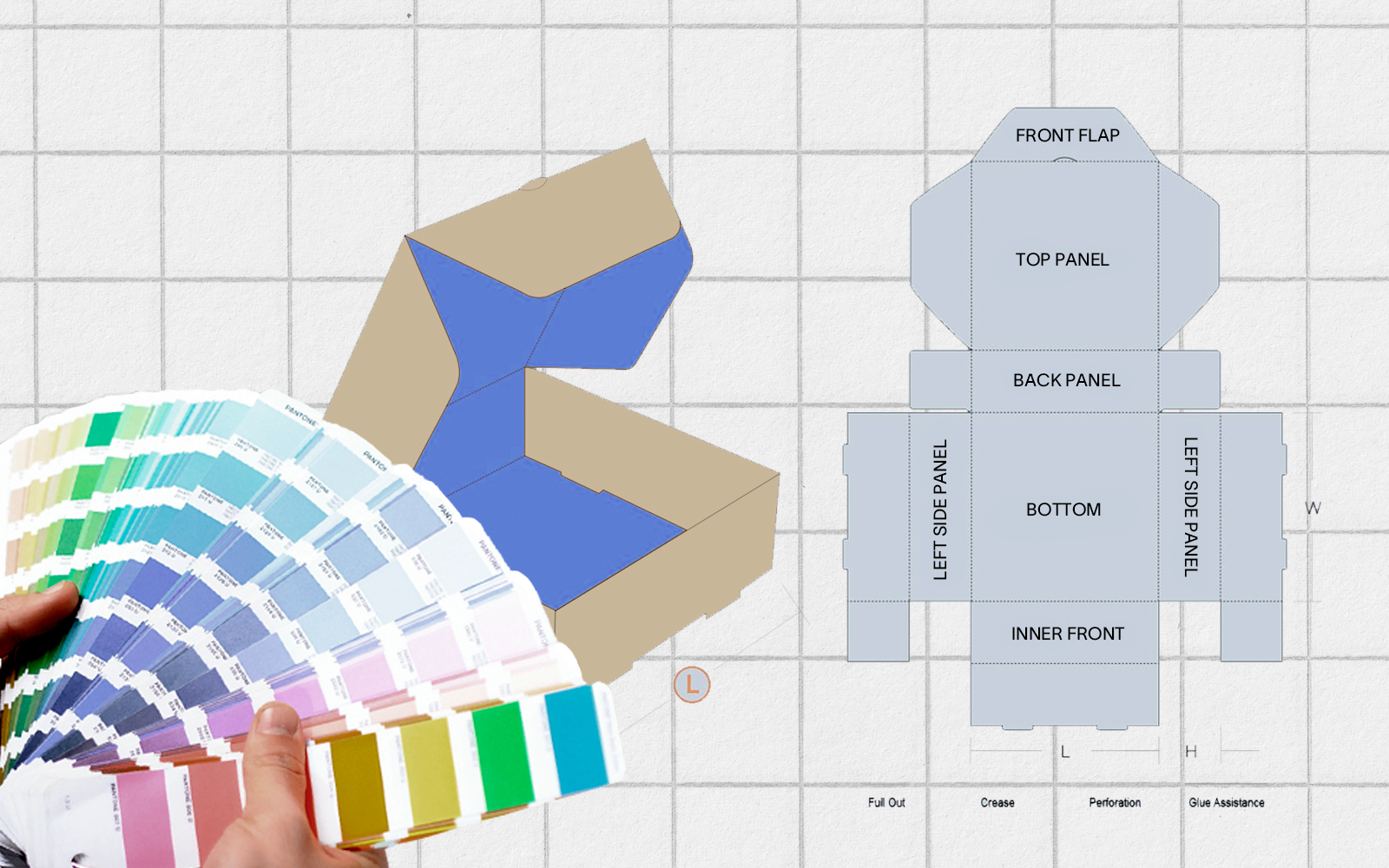

At Better Packaging Co., we have used LCAs to analyse the environmental impact of shipping envelopes made from commercially available packaging materials:

What Our LCA Reveals About Different Packaging Materials

Our study highlights significant differences in the carbon footprints of various packaging materials:

- POLLAST!C (100% Recycled Plastic) is the most environmentally friendly option with a 29% lower carbon footprint than virgin plastic

- Compostable Plastic has the highest carbon footprint of the ‘plastic’ options

- Virgin Paper & Recycled Paper high carbon footprints because of the energy consumed in their production and transportation (they weigh a lot more than plastic)

These results are consistent with LCAs commissioned by Australia Post and New Zealand Post in order to guide their packaging material decisions over recent years.

Australia Post sells customised POLLAST!C Mailers via its post offices and online store.

How to Use an LCA to Make Sustainable Packaging Decisions

Using an LCA helps businesses make data-backed decisions for sustainability:

- Identify Low-Impact Materials: Choose materials with the lowest Global Warming Potential (GWP), like POLLAST!C.

- Optimise Manufacturing: Focus on reducing energy consumption and emissions in the production process.

- Consider End-of-Life Options: Choose materials that can be easily recycled or composted.

Frequently Asked Questions About LCAs in Packaging

What is the difference between an LCA and a carbon footprint analysis?

An LCA covers the entire lifecycle of a product, while a carbon footprint analysis focuses specifically on greenhouse gas emissions.

-

LCA (Life Cycle Assessment):

- Is more comprehensive in scope.

- Assesses all environmental impacts associated with all the stages of a product's life: from raw material extraction through production, use, and disposal.

- Evaluates multiple impact categories, not just carbon emissions (e.g., water use, toxicity, eutrophication, ozone depletion).

-

Carbon Footprint Analysis:

- Narrower focus, dealing specifically with greenhouse gas (GHG) emissions.

- Measures the total amount of CO₂-equivalent emissions directly and indirectly associated with a product, process, or organisation.

- Can be "cradle-to-gate" or "cradle-to-grave" but only for carbon emissions.

Why is POLLAST!C the most sustainable option?

POLLAST!C is made from 100% post-consumer recycled (PCR) plastic, which dramatically reduces its carbon footprint compared to virgin materials. Much of the carbon footprint associated with virgin plastic is in the extraction of crude oil from the ground and the process of refining it. Because POLLAST!C is made from recycled plastic, these carbon-heavy parts of the process are not required.

How can I get an LCA for my packaging products?

Contact our team at Better Packaging Co. to discuss your packaging and sustainability goals. We are more than happy to share the LCAs we have had done for us by third party consultancies.

Further readings

- The Role of Product Stewardship in Environmental Responsibility

- POLLAST!C & Climate Change

- What is POLLAST!C?

Ready to Make Sustainable Choices?

At Better Packaging Co., we are committed to providing sustainable packaging solutions backed by data. Discuss your sustainable packaging requirements with an expert from our team.